pliion toggle joint crushing rocks

pliion toggle joint crushing rocks

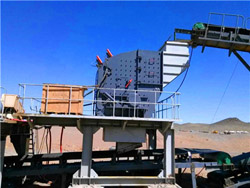

Analysis of the Single Toggle Jaw Crusher Force

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of the mechanism.A joint is a break (fracture) of natural origin in a layer or body of rock that lacks visible or measurable movement parallel to the surface (plane) of the fracture ("Mode 1" Fracture). Although joints can occur singly, they most frequently appear as joint sets and systems. A joint set is a family of parallel, evenly spaced joints that can be identified through mapping and analysis of their orieJoint (geology)

احصل على السعر

Study on the influence of joint dip angle and spacing on rock

When the joint dip angle is 0°, the crushing zone where the Von Mises stress value exceeds the rock strength forms a stress concentration zone perpendicular It is highly significant to theoretically assess the effect, under load, of initial stress and structure on the mass damage of rock mass. In this reported study, first a Strength criterion of rock mass considering the damage and

احصل على السعر

Study on Stress Evolution and Crushing Behavior of Jointed Rock

The peak stress, re ection and transmission coe cient, and fl ffi specimen failure state of rock specimens under di fferent schemes are obtained. The e ffects of con fining pressure In geology, the term "tension" refers to a stress which stretches rocks in two opposite directions. The rocks become longer in a lateral direction and thinner in a vertical Tension (geology)

احصل على السعر

Crushed Rock Toggle Joint Mechanism In Stone Crashers

toggle joint mechanism in stone crashers Mining and toggle joint mechanism used in limestone extraction. Stone quarry equipment for sale; flat operating handle for the In this paper, based on the two factors of confining pressure level and joint material properties, the influence mechanism of stress wave loading and unloading Study on Stress Evolution and Crushing Behavior of Jointed Rock

احصل على السعر

Geoengineer PLAXIS: Introduction to the Jointed Rock Model

Jointed rock masses are usually weaker, and more deformable and are highly anisotropic when compared with intact rocks. Constitutive modeling of jointed rock masses has long You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activitysbm/sbm use of toggle joint in lime stone crushers.md at master

احصل على السعر

Study on Stress Evolution and Crushing Behavior of Jointed Rock

Research Article Study on Stress Evolution and Crushing Behavior of Jointed Rock Mass under Confining Pressure and Joint Materials Wang Qirui,1,2 Zhang Qihu ,3 Yang Liyun ,3 Kong Fuli,2 Ding Chenxi,4 and Fan Junqi 2 1Department of Civil Engineering, Tsinghua University, Beijing 100084, China 2Institute of Defense Engineering, AMS, PLA, Luoyang how toggle joint work in rock crushing. how toggle joint work in rock crushing. 250tph river stone crushing line in Chile. 200tph granite crushing line in Cameroon. which can satisfy the requirements about high efficiency and coarse crushing. Output size : 140-250mm Production capacity : 2015-8895T/H. SPECIFICATIONS. Read Moreappliion of toggle joint in crushing of rocks

احصل على السعر

The Ultimate Guide to Replacing Toggle Plates in Jaw Crushers

Jaw crushers are an essential piece of equipment in many industries, including mining, construction, and recycling. These powerful machines are responsible for crushing large rocks and other materials into smaller, more manageable sizes. One critical component of jaw crushers is the toggle plate, which connects the movable jaw to the From the data in Table 1, it follows, to good approximation, that and .We shall adopt these data as we proceed. By substituting the data given in Table 1, into equation (), the following is obtained: Equation can be used to determine values of for any given value of,which represents the input motion.. In the cycle of motion of the single toggle jaw crusher Analysis of the Single Toggle Jaw Crusher Force Transmission

احصل على السعر

What Is A Jaw Crusher MEKA

In general, crushing is carried out in three stages, depending on the desired size of the material. Primary Crushing. This is the first stage of the crushing process. In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm. Secondary Crushing. This is the second stage of crushing.It is highly significant to theoretically assess the effect, under load, of initial stress and structure on the mass damage of rock mass. In this reported study, first a multi-factor couplingStrength criterion of rock mass considering the damage and

احصل على السعر

application of toggle joint in crushing of rocks

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 13.1×10⁵ kN/m² and capable of crushing 425–569 kg of rIn such cases, joints are classified into one of the following genetic types: 1. Tension Joints: Tension joints are those, which have developed due to the tensile forces acting on the rocks. The most common location of such joints in folded sequence is on the outer margins of crests and troughs.Joints in Rocks: Origin and Classification Geology Geography

احصل على السعر

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 13.1×10⁵ kN/m² and capable of crushing 425–569 kg of rIn such cases, joints are classified into one of the following genetic types: 1. Tension Joints: Tension joints are those, which have developed due to the tensile forces acting on the rocks. The most common location of such joints in folded sequence is on the outer margins of crests and troughs.Joints in Rocks: Origin and Classification Geology Geography

احصل على السعر

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE

energies for hard rocks are more than those of lower strength rocks; this arose due to more sensitivity of the hard rock to stress concentration and strain rate. According to Elisante [14], physical properties of materials such as: moisture content, structure, friability, density, hardness and crushing strength are importantWith the increase in the number of rock engineering projects, it has been recognized that the influence of joints on compressive damage of rock mass cannot be ignored. The existence of joints in the rock mass having complex surface configurations significantly influences its damage properties. Hence, a particle flow code (PFC2D) was Simulation investigation of mechanical and failure characteristics

احصل على السعر

2023/sbm appliions of toggle joint mechanism in limestone

You've already forked 2023 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivityUse the hammer to strike the cloth. You should start to hear the rocks breaking inside the cloth if you are hitting with enough force. Hammer the rocks until they are crushed as much as you want. Open How to Crush Rocks Sciencing

احصل على السعر

Evaluation of blast fragmentation effects on jaw crusher throughput

Abstract. The fragmentation rate and particle size distribution of the muckpile after blasting have important influences on the performance of subsequent mining activities such as loading, hauling, crushing, grinding, and the overall costs of the mine. Drilling and blasting are important steps in the chain of mining processes, and its resultsContribute to chengxinjia/sbm development by creating an account on .sbm/sbm toggle joint mechanism in stone crashers.md at main

احصل على السعر

Static force analysis of a single toggle jaw crusher ResearchGate

This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for crushing rocks and mineral ores to thea) Diagram of single jaw crusher, b) diagram of four-bar linkage created from vectors r1 -base, r2 -winch, r3 -fastener member, r4 -toggle plate, 1÷ 4 -angle witch define the position of members(PDF) Selected design issues of toggle plate selection on the example

احصل على السعر

(PDF) SIZE REDUCTION BY CRUSHING METHODS ResearchGate

The double jaw crusher is designed for crushing hard materials, also quarried materials, sand and gravel, and recycling. [4, 5] crusher [4] The tie rod and compression spring ensure that theJaw crushers are commonly used in the mining and aggregate industry for breaking down different types of materials, such as rocks and minerals, into smaller pieces. There are several types of jaw crushers available in the market, each with different capabilities and specifications. In this article, we will discuss the most common types of A Guide to Types of Jaw Crushers for Crushing Rocks and Minerals

احصل على السعر

DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE

Determination of the optimal angle of inclination of the toggle plate, development of jaws with varying wear rate along the crushing chamber, and development of comminution energy models that take

احصل على السعر

0086-371-86162511

0086-371-86162511

الدردشة على الانترنت

الدردشة على الانترنت