iron ore benefication product in laos

iron ore benefication product in laos

Laos: Iron Ore Market Report

Volume, value, and dynamics of the iron ore market in Laos in 2017-2021. Structure of the iron ore market in Laos: production, imports, exports, consumption. Structure of the iron This chapter briefly discusses the current scenario of the iron ore resources in India, iron ore mining methodology, beneficiation technique, and the current Iron ore beneficiation: an overview ScienceDirect

احصل على السعر

Iron ore, concentrate, not iron pyrites,unagglomerate in Laos

At the same year, Iron ore, concentrate, not iron pyrites,unagglomerate was the 8th most exported product in Laos. The main destination of Iron ore, concentrate, not iron Introduction This paper addresses the need for investments in ore beneficiation and scrap upgrading in the decades to come in order to meet demands on Driving investments in ore beneficiation and scrap

احصل على السعر

Iron ore resources and metallogenic prognosis in Laos

Publish Date: 15 March 2012. Abstract. The data processing and field investigation indicate that there are 42 iron deposits (spots) which have been found in Laos. Some of them Laos Exports of iron ores and concentrates to China was US$131.86 Million during 2021, according to the United Nations COMTRADE database on international trade. Laos Laos Exports of iron ores and concentrates to China

احصل على السعر

Iron ore beneficiation: an overview ResearchGate

The iron-making process requires high-quality raw materials, with Fe ≥ 64% and <2% alumina and silica each, to enhance blast furnace productivity at a given Iron ore resources and metallogenic prognosis in Laos. Lei Jiu-yun. Published 2012. Geology. Resources Survey and Environment. The data processing and field Iron ore resources and metallogenic prognosis in Laos

احصل على السعر

(PDF) An overview of the beneficiation of iron ores

Research regarding iron ore flotation began in 1931, demonstrating that reverse cationic flotation is a very efficient method for beneficiating oxidised iron ores. This method can also be appliedIndian iron ores are rich in iron (Fe) content, with 62 to 64 percent Fe, and contain 2.5 to 3 percent alumina. The major iron-bearing minerals are briefly described in Table 1. Due to the high alumina content, the Indian iron ore beneficiation process has not yet found much importance compared with those in the rest of the world.Development of process for beneficiation of low-grade iron ore

احصل على السعر

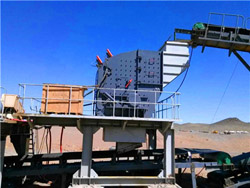

What are the processes of iron ore beneficiation? LinkedIn

Here are the common processes used for iron ore beneficiation: 1.Crushing and Grinding: The ore is first crushed into smaller pieces by primary crushers. It is then ground to a fine powder in aThis research is aimed at the up-gradation of indigenous Pakistani iron ore, i.e., Dilband iron ore (hematite), by utilizing common metallurgical processes. First, the magnetic properties of the ore were determined. Initially, the iron ore samples contained 34 wt. % Fe in addition to other gangue materials. Therefore, the ore was subjected to a Beneficiation of Low-Grade Dilband Iron Ore by Reduction

احصل على السعر

Beneficiation Study of Barsuan Iron Ore Slime to Produce

It is observed that, quality of the slime could be improved significantly. However, the concentration grade is about 62.48% indicating the requirement of further concentration process. The Tabling results indicate possibility of getting better grade product. The grade improved substantially from 54.93 to 62%.The ore was firstly preconcentrated by a dry low-intensity magnetic separator (DLMS) at a magnetic intensity of 2500Oe, and then ground to -0.074mm 53%, followed by a wet low-intensity magnetic separator (WLMS) to recover iron minerals. An iron concentrate assaying 49.22% Fe can be obtained at a recovery of 46.23%.Iron Ore Beneficiation PDF Iron Ore Iron Scribd

احصل على السعر

en/available iron ore in laos.md at main dinglei2022/en

Oct 10,2016.Laos' largest mineral resource is iron ore,with reserves estimated at 1,000 Mt with over 60% Fe content.The deposits mostly lie in Xien.China vs.Laos Country Comparison IndexMundiModern day Laos has its roots in the ancient Lao kingdom of Lan Xang,established in the 14th.Natural resources,coal,iron ore,petroleum,natural 22.4: Beneficiation. Beneficiation is any process which removes the gangue minerals from ore to produce a higher grade product, and a waste stream. Beneficiation may involve physical or chemical processes. Often, as in the case of panning for gold, the desired ore or metal is denser than the gangue.22.4: Beneficiation Chemistry LibreTexts

احصل على السعر

Processes for Beneficiation of Iron Ores IspatGuru

Processes for Beneficiation of Iron Ores. satyendra; March 28, 2015; 0 Comments ; Heavy media separation, Iron ore, iron ore beneficiation, Jigging, magnetic separation, washing, Processes for Beneficiation of Iron Ores Iron is an abundant element in the earth’s crust averaging from 2 % to 3 % in sedimentary rocks to 8.5 % in Costs and benefits of decreasing the silica content in iron bearing raw materials in the DR-EAF supply chain. The black arrows indicate the changes in loss of iron to tailings, scrap residue or slag.(PDF) Driving investments in ore beneficiation and scrap upgrading to

احصل على السعر

RU2500822C2 Iron ore benefication method Google Patents

FIELD: mining. SUBSTANCE: method involves crushing and pulverisation of crude ore, its selective flocculation, deslurrying and magnetic separation of deslurrying sands so that iron-ore concentrate is obtained, at pulverisation of crude ore, it is processed with a disperser containing silicate salts, the consumption of which is 0.2-0.6 kg per 1. Introduction. Iron-containing ore beneficiation includes several stages. For example: crushing to −30 mm size class and rough magnetic separation, further crushing of the recovered magnetic product Beneficiation of Magnetically Separated Iron

احصل على السعر

(PDF) Beneficiation of Low-Grade Dilband Iron Ore by

First, the magnetic properties of the ore were determined. Initially, the iron ore samples contained 34 wt. % Fe in addition to other gangue materials. Therefore, the ore was subjected to a highBeneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.This also applies to iron ores of the non-magnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per Beneficiation of Iron Ore 911 Metallurgist

احصل على السعر

Beneficiation of Clay-Rich High-LOI Low-Grade Iron Ore Fines

The unutilized iron ore fines (IOF, − 10 mm, 45% to < 60% Fe(T)) left at various mine sites during blasting and processing are rich in goethetic-hematite associated with high clay and considered a potential iron ore resource. The variation of loss on ignition (LOI) from mines to mines is based on the goethite and clay mineral content. The clay Ore blending is an essential part of daily work in the concentrator. Qualified ore dressing products can make the ore dressing more smoothly. The existing ore blending modeling usually only considers the quality of ore blending products and ignores the effect of ore blending on ore dressing. This research proposes an ore blending Applied Sciences Free Full-Text A Method of Ore Blending

احصل على السعر

Treatment of iron ore beneficiation plant process water by

Process water collected from the iron ore beneficiation plant was treated by electrocoagulation (EC) process to make it suitable for reuse or safe for discharge. Experimental studies were carriedIn terms of the traditional inputs, such as coking coal and iron ore, Oman has no significant reserves. While the Gulf Mining Group is active in developing iron ore mines in Oman, currently there is no significant domestic production in The Sultanate. Oman has experienced steady expansion of their iron oreKey Points Downstream Beneficiation Case Study: Oman

احصل على السعر

CFlo World

A comprehensive range of wet processing equipment for quarries,mines and recycling operations.An iron ore assaying 57% Fe could be upgraded to an iron concentrate of 63–64% Fe at a Fe recovery of more than 85% under the conditions such as temperature: 1050 °C, roasting time: 90 min and charcoal (reductant): 4%. In the same way, Yu et al. [74] applied reduction roasting for a low-grade carbonate-bearing iron ore comprising of A review on the enrichment of iron values of low-grade Iron ore

احصل على السعر

0086-371-86162511

0086-371-86162511

الدردشة على الانترنت

الدردشة على الانترنت