jaw plates of stone jaw crusher heat treatment

jaw plates of stone jaw crusher heat treatment

Crusher Jaw Plate Heat Treatment YouTube

Crusher Jaw Plate Heat Treatmenthttps://mgscasting/jaw-crusher-parts-2/We know that the jaw crusher spare parts maily include the fixed jaw plate and the movable jaw plate.DSMAC's Jaw crusher plates are Jaw Crusher Plate > Crusher Parts > Products > DSMAC

احصل على السعر

(PDF) Optimum design and analysis of (the) swinging

Design of lighter weight jaw crusher will require a more precise accounting of the stress and deflections in the crushing plates Jaw crusher plates are classified into three main categories: fixed jaw plates, movable jaw plates, and cheek plates. Each category of jaw crusher plate plays a specific role in the crushing Mastering Jaw Crusher Plates: A Comprehensive Guide

احصل على السعر

Optimisation of the swinging jaw design for a single toggle jaw

Job Maveke Wambua & Tien-Chien Jen International Journal on Interactive Design and Manufacturing (IJIDeM) ( 2022) Cite this article 228 Accesses relieving heat treatment in order to pre vent residual stresses from the welding The single-toggle jaw crusher with the largest antifriction 100 150 swing jaw moves Industrial Solutions Jaw crushers ThyssenKrupp

احصل على السعر

Theoretical Analysis of Swing Jaw Plates used in Heat Exchanger

PDF A jaw crusher breaks minerals, ores of high strength. The stiffness of swing jaw plate has not been varied with changes in rock strength. Thus Find, read by using ANSYS software. The changes found in corrugated swing jaw plates behaviour are calculated with the traditional jaw. The modified stiffened plate model is estimated to Theoretical Analysis of Swing Jaw Plates used in Heat Exchanger

احصل على السعر

Introduction of crusher jaw plate MIXING AND CRUSHING

The jaw crusher is a crushing machine that everyone is very familiar with. We also wrote an article about the jaw crusher plates last time, but in the last comment, someone asked if there was a detailed introduction to the jaw plate of the crusher. so we wrote this article, this is an article about the jaw plate of the crusher, I hope it can help Maharsh Metal Heat Treatment. Ahmedabad No. 46, Giriver Globe Industrial Park, Kathawada, Ahmedabad 382350, Dist. Ahmedabad, Gujarat. Nandhi cast iron stone crusher jaw plate, for crushing machi Hardox 450 jaw crusher steel plate, size: 1500/2000 x 6000; Hardox 450 jaw crusher plate;Jaw Plates Crusher Jaw Plate Latest Price, Manufacturers

احصل على السعر

Low cost Stone Crusher Manufacturer India Jaw

A 30 TPH Jaw crusher price in Delhi is Rs. 65,00,000 lacs. A mini jaw crusher machine price starts from Rs. 15,00,000 lacs. You can contact Maan Global Industries a leading jaw crusher supplier in Virendrasinh N Dodiya, Prof. Vijay Pipalia and Prof. Dhaval P Patel, “Investigation of Effect of Without Stiffener on Swing Jaw Crusher Plate by Finite Element Analysis” IJSRD nternational Journal for Scientific Research & Development| Vol. 3, Issue 01, 2015, ISSN (online): 2321-0613 [11] S. D. Pandey, V. K. Nema and S. K. Shukla, “ IRJET- Computer Aided Design and Finite Element Analysis of Swing Jaw

احصل على السعر

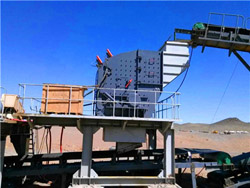

Jaw Crusher Jaw Crusher Types Jaw Crusher Prices Fabo

Jaw Crusher Working Principle. Jaw crushers are a type of crusher with a unique system. Jaw crusher, which is a very strong type of crusher, performs the crushing process with the help of two plates. One of these plates works by making constant, the other by making elliptical movements. The stones are shattered by the pressure exerted by theseJaw crusher is the key crusher equipment for stone crushing production. Many customers will meet various kinds of fault problems during production process, which will affect the whole production schedule. Here, Luoyang Dahua summarizes the common failure and treatment of the jaw crusher. A.The main engine stops suddenly. Failure cause:Failure Analysis of Jaw Crusher Luoyang Dahua

احصل على السعر

Jaw Plate Crusher Jaw Plate Price Discount EB Castworld

Jaw plate is the main wear-resistant part of the jaw crusher: the movable jaw plate and the static jaw plate. According to the different types of the jaw crusher, there are various models and sizes. The jaw plate is made of new high manganese steel, super high manganese steel, Super high manganese steel and other materials are suitable for jaw plates of stone jaw crusher heat treatment T03:01:10+00:00 News Crusher Jaw Plates Heat Treatment HG. The heat treatment process curve is shown in the figure It can be seen from the figure that the tooth plate is installed in a furnace below 300 ℃ and is kept at 300 ℃ for a period of time,jaw plates of stone jaw crusher heat treatment

احصل على السعر

EXPERIMENTAL EFFECT ON JAW CRUSHER PLATE IJARIIE

This paper shows the tested in jaw crusher weight loss in plate due to impact, abrasive material and combination of both using stone. The wear rate is determined by weight reducing in the specimen of jaw plate. Total plate is running near about 5 months which wear more 40%. After testing it is found that wear in stationary jaw plate andThe heat treatment process curve is shown in the figure. It can be seen from the figure that the tooth plate is installed in a furnace below 300 ℃ and is kept at 300 ℃ for a period of time, so that the temperature of each part of the casting tends to be uniform, reduce internal stress, and prevent the casting from cracking due to excessive temperature differences News Crusher Jaw Plates Heat Treatment

احصل على السعر

Jaw Crusher Parts Casteel Foundry

CASTEEL Jaw plate are manufactured with High Manganese steel of Mn13, Mn14Cr2, Mn18Cr2, Mn22Cr2 Meat With ASTM A128 Gr A & B2 & B3, BS 3100 Gr BW10, SABS 407,we also do customized material with Molly Throughout special heat-treatment process The Jaw plate has a service life 30% longer than those of traditional high manganese steel! Swing Jaw Plates (1200Χ900Χ216) with Stiffeners. Fig.15. Swing Jaw Plates (1200Χ900Χ224) with Stiffeners. D. Swing Jaw Plates Static Stress Analysis with Stiffeners Below is a finite element representation of the stiffened plate shown in Figs.16 to 19. The plate is thick, therefore thick plate theory applies.Design & Analysis of Swing Jaw Plate of Jaw Crusher

احصل على السعر

Fixed Jaw Plate for Jaw Crusher EB Castworld % Jaw

Make your jaw crusher experience less downtime; More economical, save your cost 40-60%; Stronger wear resistance reduce maintenance costs; Advanced manufacturing technology, produce strictly according to Business listings of Jaw Plates, Crusher Jaw Plate manufacturers, Maharsh Metal Heat Treatment. Ahmedabad No. 46, Giriver Globe Industrial Park, Kathawada, Ahmedabad Crusher Mild Steel Jaw Plate, For Braking Stone, Rectangle ₹ 110/ Kg Get Latest Price . Material: Mild Steel.Jaw Plates In Ahmedabad (जॉ प्लेट, अहमदाबाद)

احصل على السعر

Crusher Jaw Plate Heat Treatment YouTube

Crusher Jaw Plate Heat Treatmenthttps://mgscasting/jaw-crusher-parts-2/9.3.1.1 Jaw Crusher Operating Principles. Fixed and movable jaw plates are the two main components. A motor-driven eccentric shaft through suitable hardware makes the movable jaw plate travel in a regulated track and hit the materials in the crushing chamber comprising a fixed-jaw plate to assert compression force for crushing. 9.3.2 CoalCrusher an overview ScienceDirect Topics

احصل على السعر

Jaw Plate Stone Crusher Spare Parts, Crusher Hammer, Crusher

DSMAC's jaw crusher plates are made of super high manganese steel, therefore they have a service life 50~100% longer than those made of traditional high manganese steel. Every model of PE series jaw crushers in DSMAC is tested for shock, stress, strain, thermal loading, deformation, vibration and noise under a wide range of load conditions.Find here Jaw Plates, Crusher Jaw Plate manufacturers, Maharsh Metal Heat Treatment Ahmedabad. Call Now 08047639973 Get Best Price. Manganese Steel Jaw Plates, For Crusher Machine, Manganese Crusher Jaw Plate, For Stone Crushing Machine ₹ 2,35,000/Piece. Material: Manganese.Jaw Plates Crusher Jaw Plate Latest Price, Manufacturers

احصل على السعر

4 Commonly Used Material Types for Jaw Plate Wear Spare Parts

We will introduce in detail the commonly used material types for the jaw plate of the jaw crusher as below: High manganese steel. High manganese steel is the traditional material of the jaw plate of the jaw crusher. It has good toughness and good deformation and hardening ability. However, due to the unreasonable structure of the jaw Stone Crusher Jaw Plates. Heat treatment is commonly used within the mining industry as a way to harden metal components, including tools such as cutter heads, buckets, hammerheads, etc. Several different heat treatments are available depending on what type of component is required.Resminer Your Prime Stone Crusher Jaw Plate Manufacturer

احصل على السعر

0086-371-86162511

0086-371-86162511

الدردشة على الانترنت

الدردشة على الانترنت