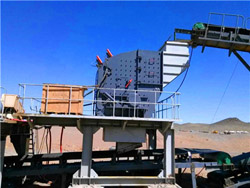

the jaw crusher where the quality is the best

the jaw crusher where the quality is the best

Influence of jaw crusher parameters on the quality of

Jaw crusher performance can be optimised for increased aggregate quality. Calculation of flakiness index hides variation of particle shape within a gradation. Mechanical properties are highly affected by sample preparation.The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their Jaw Crushers high quality and reliability from RETSCH

احصل على السعر

Jaw Crusher an overview ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in Improved Product Quality: A properly sized and configured jaw crusher can improve the quality and consistency of the final product. This can be particularly important in applications where product Choosing the Right Jaw Crusher Size and Capacity for

احصل على السعر

McLanahan Jaw Crushers

1:59 A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the Currently, the dimensions of the largest Blake-type jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW. Crushers of this size are Jaw Crusher ScienceDirect

احصل على السعر

Optimisation of the swinging jaw design for a single toggle jaw

Abstract. This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry jaw crusher BR380JG-3. mobile. Capacity: 50 t/h 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating Jaw crusher, Jaw crushing and screening plant All

احصل على السعر

How Does a Jaw Crusher Work Jaw Crusher Kemper

Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney Blake ), have long been the standard Parameter and Price of 200t/h River Stone Crusher. With the rapid technology development, some fields such as express train, hydropower, railway, building construction step in a golden developing zone, which has also raised greater demand on aggregates, so is on the 200t/h river stone crusher. Read the rest >.Stone Crushing,Mobile Stone Crushing Machine,Ore Crusher

احصل على السعر

The 10 Best Crusher Manufacturers & Brands in 2023

TON Outotec, a new company specializing in mineral processing, metal processing, and recycling, is also featured, along with Kleemann, renowned for its innovative strength and high-quality The Trio® CT Series jaw crusher is frequently used in mining to process precious metals and a wide spectrum of other minerals. It is also used to process hard rock, sand, concrete, asphalt and slag within the aggregates industry. Recommended Industries: Mining, Sand and Aggregates, Infrastructure, General Industry.Our Range of Trio® Jaw Crushers Weir

احصل على السعر

Jaw Crusher Yumpu

The JC2501 crusher is unlike ordinary toggle jaw crushers as it uses an<br /> oscillating motion, via a Pitman/crank arm arrangement, to rapidly reduce<br /> near jaw size lumps to 2 mm in a single step.<br />Jaw crusher units with extra-long, articulated crusher jaws prevent coarse material from blocking while moving all mounting elements of the crusher jaw from the wear area. A more even material flow may be affected if the transfer from the prescreen or the feeder trough is designed so material simply tilts into the crushing jaw.P&Q University Lesson 7: Crushing & Secondary Breaking

احصل على السعر

A fundamental model of an industrial-scale jaw crusher

Abstract. In this study, an analytical perspective is used to develop a fundamental model of a jaw crusher. Previously, jaw crushers were modelled in regard to certain aspects, for example, energy consumption (Legendre and Zevenhoven, 2014) or kinematics (Oduori et al., 2015). Approaches to date have been mainly property specific.There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits.Types of Crushers: What You Need to Know Machinery Partner

احصل على السعر

Automation experimental studies of grinding process in jaw crusher

In the presented work, a model of the crushing process in a jaw crusher using the Discrete Element Method (MDE) was realized. The use of modern software allowed studying in detail the impact ofThe moving jaw plate is mounted on the pitman, which is given a reciprocating motion. Crushing takes place when the pitman moves toward the stationary jaw. There are two main types of jaw crushers single toggle and double toggle. The single-toggle jaw crusher features a pitman mounted on an eccentric shaft at the top.Selecting the Right Crushing Equipment Agg-Net

احصل على السعر

What Is A Jaw Crusher MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within the ore and to release them from one another. 4.)Particle size distribution curves of recycled aggregates from building demolition concrete crushed by jaw and impact crushers. The jaw crusher produced 60% of coarse aggregates in weight, whereas the impact crusher produced 49% coarse aggregates. The proportion of particles finer than 0.15 mm is around 7–8% weight for Concrete aggregates properties crushed by jaw and

احصل على السعر

Choosing the Right Jaw Crusher Size and Capacity for

Maximizing crusher performance and productivity requires selecting the right jaw crusher size and capacity. Learn how to determine the optimal size and capacity for your application, and discover the Jaw crushers are utilized extensively in the industries of mining, metallurgy, building materials, ceramics, and engineering of massive minerals with small and medium particle size crushing [1] [2Performance Parameters of Jaw Crushers Download Table

احصل على السعر

Influence of jaw crusher parameters on the quality of primary

Jaw crusher Parameter study Aggregate quality Crusher operation ABSTRACT A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate,For crushing materials with different characteristics, the corresponding crushing chamber should be selected so as to achieve the maximum efficiency and the best quality of production. (3)MaterialHow to Choose Jaw Crusher LinkedIn

احصل على السعر

Know-how RUBBLE MASTER

Other common combinations consist of a jaw crusher, cone crusher and screen, or a jaw crusher and two downstream cone crushers to produce high quality cuboid aggregate and a secondary screen/screens. There are also applications where a scalper is placed in front of the jaw crusher, especially when the feed material is high in fines content.Crusher. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore ), so that pieces of differentCrusher

احصل على السعر

MC 110i EVO2 Mobile jaw crushers Kleemann Wirtgen Group

Contact. The jaw crusher MOBICAT MC 110 EVO2 is used for the precrushing of almost all natural rock and in recycling. Compact dimensions, efficient prescreening, simple operation via SPECTIVE as well as impressive production output characterize the efficient key player. Continuous Feed System (CFS) for optimal crusher feeding.When it comes to considerations between impact crusher vs jaw crusher, the main difference is how they are used. The first one is a primary crusher while the latter is a secondary crusher. An impact crusher can crush hard materials while a jaw crusher can crush brittle ones. A jaw crusher is suitable to use for harder rocks such as Impact Crusher vs. Jaw Crusher Multico Prime Power Inc.

احصل على السعر

jaw crusher 英中 Linguee词典

大量翻译例句关于"jaw crusher" 翻译器. Translate texts with the world's best machine translation technology, chairman of jinfa, general manager Li Jiankun with the staff, to science and technology, the implementation of high-quality brand strategy, creating customer satisfaction projects,

احصل على السعر

0086-371-86162511

0086-371-86162511

الدردشة على الانترنت

الدردشة على الانترنت